5 Simple Techniques For precision machining

Based on our shoppers’ requirements and products blueprints, we deliver tailor made threaded components which might be precise in requirements and excellent in top quality.

Outstanding customer support. I produced a comment on Instagram about my lever slipping and not tightening... down and so they right away hit me up, advised me to electronic mail them And they'd look after it ASAP.

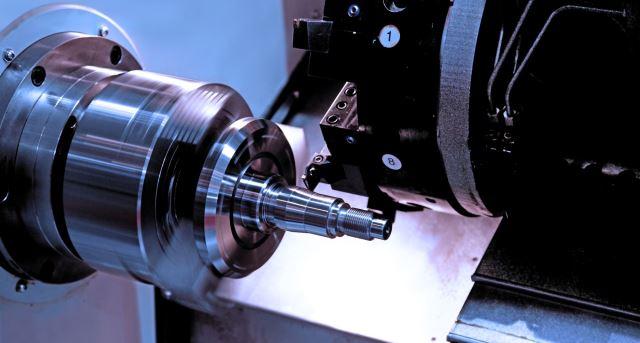

The main motion is furnished by rotating the workpiece, and the feed movement is attained by transferring the cutting Device little by little in a very course parallel on the axis of rotation on the workpiece.

5 Simple Techniques For machining

Elcon makes use of several different etchants, some proprietary, to process lots of components together with molybdenum, tungsten, titanium, and gold. We benefit from both dry and liquid resist based upon your application. Even the dimensions in the steel sheet is optimized depending on the tolerances and geometry. Therefore, Elcon is ready to generate ï¬ner geometry with bigger precision than a regular etching approach.

: to procedure by or as though by equipment Primarily : to lessen or finish by or as though by turning, shaping, planing, or milling by machine-operated resources

Considering that the arrival of latest technologies while in the put up–Globe War II period, which include electrical discharge machining, electrochemical machining, electron beam machining, photochemical machining, and ultrasonic machining, the retronym "standard machining" can be used to differentiate All those common technologies with the newer ones.

These devices are operated by specialised and educated machinists. The precision machining system consists of a reducing Software that eliminates product with the workpiece. To ensure that the cutting Device to do its work, it have to be moved in Instructions specified to create the right cut. This primary motion is known as the “cutting pace.†The workpiece will also be moved, generally known as the secondary movement of “feed.†Jointly, these motions as well as the sharpness on the cutting tool allow the precision machine to work. Learn More:

Wire Electrical Discharge Devices (EDMs) consider an entirely distinct method of CNC machining in which they trust in conductive elements and electrical power to erode the workpiece. This process can Reduce any conductive material, which include all metals.

Facts About precision machining Revealed

Stainless-steel sintering furnace by sunkoo device is product of stainless steel, resistant to acid and alkali corrosion, no rust, big selection of purposes, internal might be tailored based on the kind of sintered products and solutions, personalized pallets or trailers, customized aluminum panels to create the product evenly heated.

These devices can also be vital to other manufacturing processes. Such as, the molds demanded for injection molding are CNC machined to make sure the precision of both the mildew plus the plastic portion it will make.

During the vertical mill the spindle axis is vertically oriented. Milling cutters are held while in the spindle and rotate on its axis.

A third style also exists, a lighter machine, called a mill-drill, that's a close relative of your vertical mill and very well known with hobbyists. A mill-drill is similar in fundamental configuration to a small drill push, usinagem but equipped having an X-Y desk. They also commonly use more potent motors than a comparably sized drill push, with potentiometer-controlled velocity and generally have a lot more large-duty spindle bearings than the usual drill press to manage the lateral loading to the spindle that is definitely made by a milling operation. A mill drill also commonly raises and lowers the whole head, such as motor, often over a dovetailed vertical, in which a drill push motor stays stationary, even though the arbor raises and lowers in a driving collar. Other variances that independent a mill-drill from the drill press may be a good tuning adjustment with the Z-axis, a far more specific depth prevent, the capability to lock the X, Y or Z axis, and often a procedure of tilting the head or the whole vertical column and powerhead assembly to allow angled chopping.

Details, Fiction and machining

As a professional undertaking, machining is usually done inside a device shop, which consists of a number of workrooms that contains major equipment resources.